Digitization of production

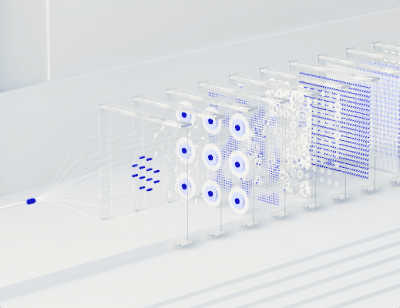

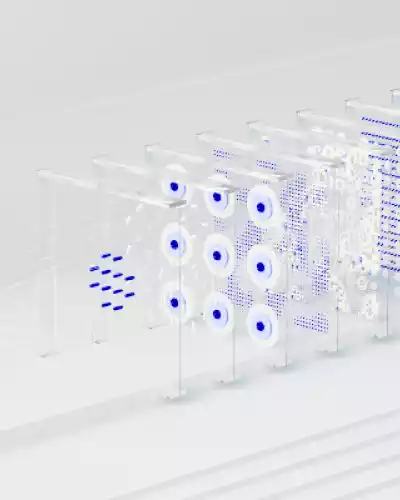

We link the data from incoming inspection QC with machine data and sensor data from production and final inspection. We act as an extension of the MSAT and production team. We contribute our experience with GMP adaptations of existing dossiers.

We build our own digital models according to the most modern methods of pattern recognition (SIMCA, PCA, PCR, PLS, SPC etc).

We mainly use existing data.

This allows you to control production highly efficiently and avoid wasting unused data.

We relocate part of the QC within production.

This reduces throughput times by up to 70%.

More than 20 years of experience in manufacturing, quality and a keen interest in models pays off.